ALLOY TUBE ALLOY TUBE TUBE Cadaadis Sarreya

Sharaxaada

OD: 6-720MM

WT: 0.5-120MM

Dhererka:3-16M

Codsiga: Batroolka, Kiimikada Kiimikada, Korontada, Kuleyliyaha

Heerka:ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88,GB5310-95

Waxyaabaha: P5,T5,P11,P12,STFA22,P22,T91,T9,WB36

Tuubbada Alloy waa nooc ka mid ah tuubooyinka birta ah ee birta ah, waxqabadkeedu aad ayuu uga sarreeyaa tan guud ee birta birta ah, sababtoo ah nooca birta ah waxay ka kooban tahay Cr badan, caabbinta heerkulka sare, caabbinta heerkulka hooseeya, waxqabadka iska caabinta daxalka ayaa aad uga fiican kuwa kale. Dhuumaha birta, sidaas darteed tuubada daawaha ayaa si weyn loo isticmaalaaee batroolka, hawada sare, kiimikaad, tamarta korontada, kuleyliyaha, militariga iyo warshadaha kale.

Tuubbada Alloy waxaa loola jeedaa isticmaalka daawaynta extrusion processing galay wax tuubooyin bir ah, kaas oo yeelan kara mid ama in ka badan xiran iyada oo godad, dhumucdiisuna waxay derbiga iyo qaybta cross unit, loo isticmaalo baabuurta, maraakiibta, aerospace, duulista, korontada, beeraha, farsamo electro. guriga iyo warshadaha kale.

Tilmaamid

Halabuurka Kiimikada

| C,% | Mn, % | P, % | S,% | Si,% | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Guryaha Makaanikada

| Xoogga Jilbaha, MPa | Xoogga Wax-soo-saarka, MPa | Kordhinta, % |

| 415 min | 205 daq | 30 daqiiqo |

Dhexroorka & Dulqaadka

|

ASTM A450

| Kulul duuban | Dhexroorka ka baxsan, mm | Dulqaad, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| ASTM A530 & ASTM A335 | NPS | Dhexroor ka baxsan, inji | Dulqaad, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ± 1% |

Dhumucda gidaarka & Dulqaadka

| ASTM A450 | Kulul duuban | Dhexroorka ka baxsan, mm | Dulqaad,% |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| ASTM A530 | NPS | Dhexroor ka baxsan, inji | Dulqaad,% |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

Heerka

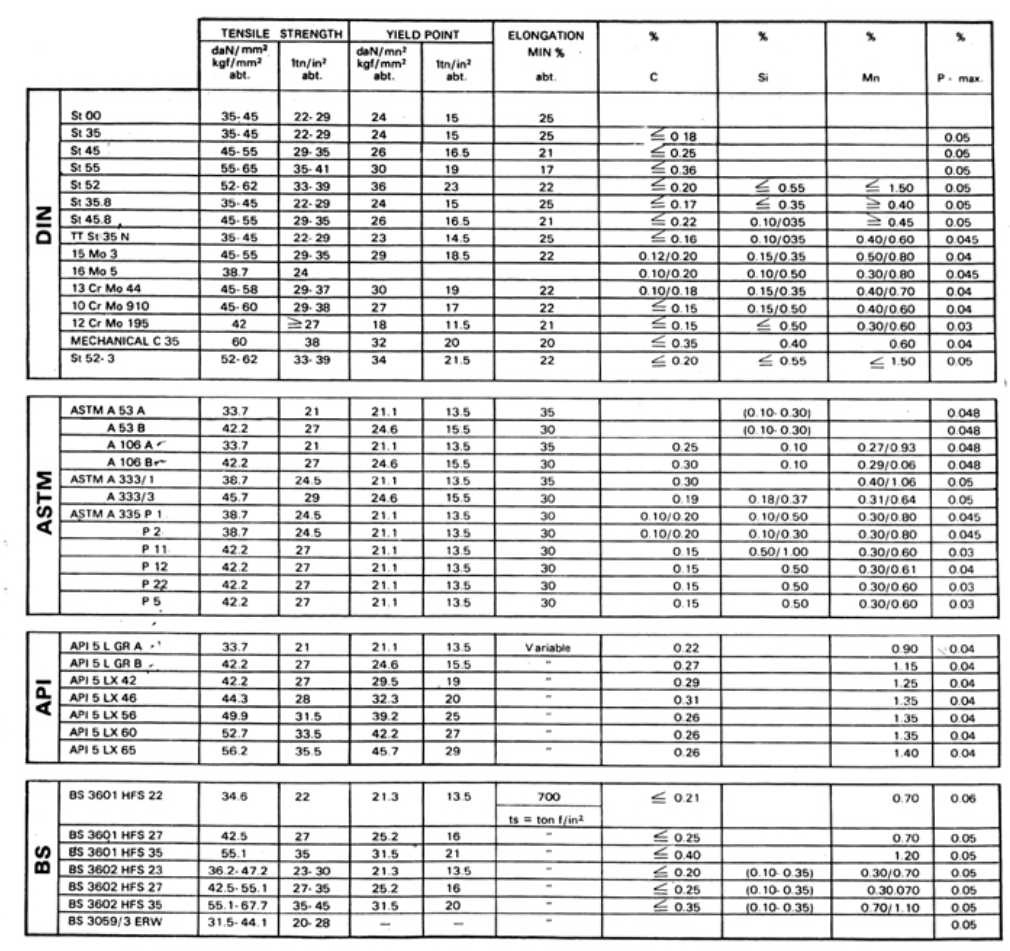

ASTM A335 oo loogu talagalay Dhuumaha Birta-Ferritic Alloy-Steel ee Adeegga Heerkulka Sare

ASTM A519- loogu talagalay Kaarboonka iyo Tuubooyinka Makaanikada ee Birta Daawaha ah

ASTM A213- loogu talagalay Ferritic iyo Austenitic Alloy-Steel Boiler, Kuleyliyaha Sare, iyo Tubooyinka Kulaylka

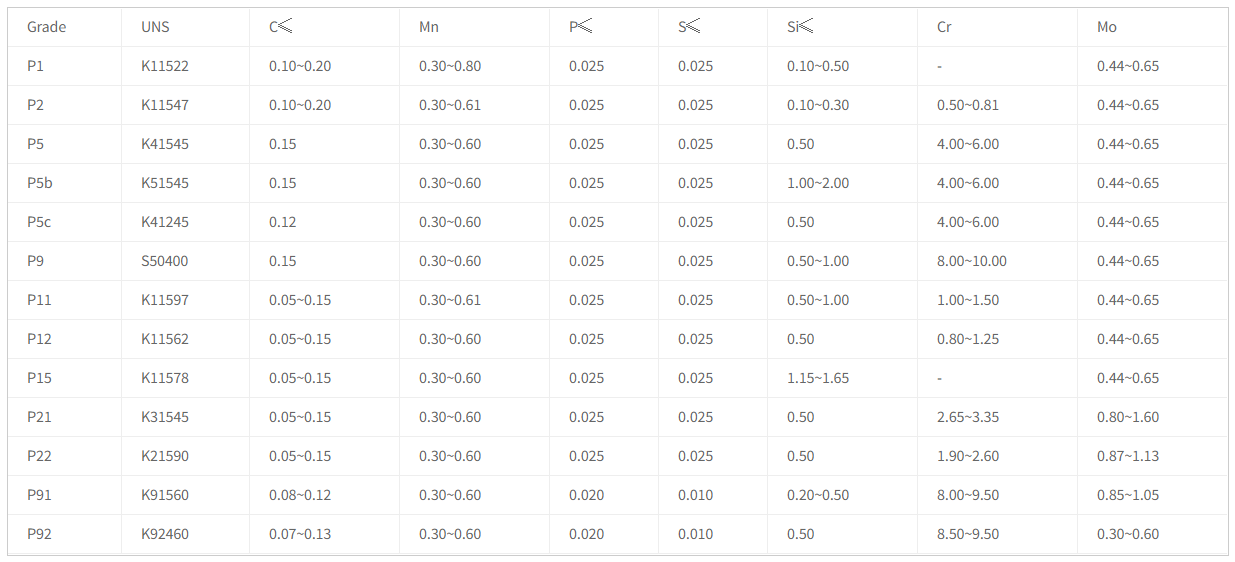

ASTM ASME (S) A-335/(S)A-335M Darajada iyo Halabuurka Kiimikada

Fiiro gaar ah: (S) A335 P91 ka kooban kiimiko kale waa: V 0.18 ~ 0.25;N 0.030 ~ 0.070;Ni ≤ 0.40;Al ≤ 0.04;Nb 0.06 ~ 0.10

(S) A335 P92 kale oo ka kooban kiimiko waa: V 0.15 ~ 0.25;N 0.030 ~ 0.070;Ni ≤ 0.40;Al ≤ 0.04;Nb 0.04 ~ 0.09;W 1.5 ~ 2.00;B 0.001 ~ 0.006

Rinjiyeynta & Dahaarka

Daahan madow, saliid / varnish, FBE, 2PE, 3PE, galvanized iwm Faahfaahin baakad: Xirmooyinka xirmooyinka ama shuruudaha macmiilka

Xirxirida & Rarista