BIRTA BIRTA KAARBON EE TUBE ERW ALAAXAY TUBE TUBE SSAW

Sharaxaada

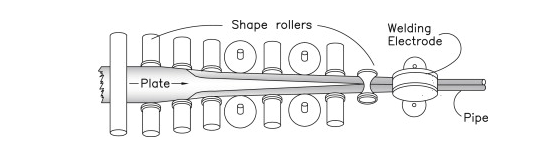

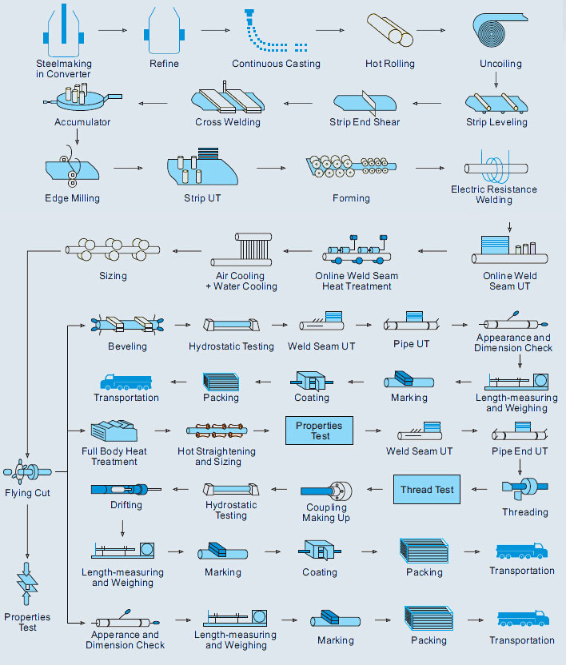

Tuubbooyinka dabada ka samaysan ayaa la sameeyaa iyadoo quudinaysa saxan bir ah oo kulul iyada oo loo marayo qaabab u rogi doona qaab wareeg ah oo bannaan.Xoog isku dhufashada labada daraf ee saxanka waxa ay soo saari doontaa isku xidhan ama tol.Jaantuska 2.2 wuxuu muujinayaa saxanka birta marka uu bilaabayo habka samaynta tuubooyinka dabada-alxanka

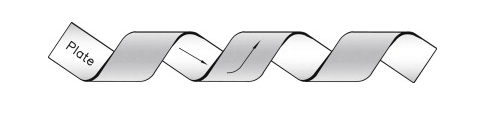

Inta ugu yar ee saddexda hab ka mid ah waa tuubooyin alxan leh.Tuubbada alxanka leh waxa ay samaysaa in ay maroojiso fiilooyinka birta ah una rogta qaab wareeg ah, oo la mid ah tiirka timo-jaraha, ka dibna alxanka halkaas oo cidhifyadu ay isku biiraan si ay u sameeyaan tol.Tuubada noocaan ah waxay ku xaddidan tahay nidaamyada tuubooyinka iyadoo la adeegsanayo cadaadis hooseeya sababtoo ah darbiyadeeda dhuuban.Jaantuska 2.3 waxa uu tusinayaa tubbada alxanka leh sida ay u muuqato ka hor alxanka.

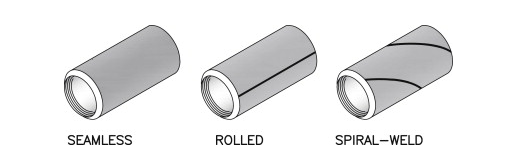

Mid kasta oo ka mid ah saddexda hab ee loo soo saaro tuubada waxay leedahay faa'iidooyin iyo faa'iido darrooyinkeeda.Tubooyinka dabada-weldedka ah, tusaale ahaan, waxay ka samaysan tahay saxan duuban oo leh dhumucdiisuna tahay darbi isku mid ah waxaana laga eegi karaa cilladaha ka hor samaynta iyo alxanka.Habkan wax soo saarka ayaa si gaar ah faa'iido u leh marka loo baahan yahay derbiyo khafiif ah iyo dherer dheer.Sababtoo ah tolida alxanka ah, si kastaba ha ahaatee, mar walba waxaa jira suurtagalnimada cilladaha ka baxsanaya hubinta tayada tayada ee tirada badan ee la sameeyay inta lagu jiro habka wax soo saarka.

Natiijo ahaan, Machadka Heerarka Qaranka ee Mareykanka (ANSI) wuxuu sameeyay habraacyo adag oo ku saabsan soo saarista tuubooyinka.Xeerka tuubooyinka cadaadiska B31 ayaa loo qoray si loo maamulo samaynta tuubooyinka.Gaar ahaan, koodka B31.1.0 wuxuu ku meeleeyaa qodobka xoogga ah ee 85% ee tuubada duuban, 60% tuubada alxanka leh, iyo 100% waxtarka tubada aan fiicnayn.

Guud ahaan, dhumucyada derbiga ballaaran waxaa lagu soo saaraa habka aan fiicnayn.Si kastaba ha ahaatee, isticmaalka badan ee cadaadiska hoose ee tuubooyinka, habka alxanka ee joogtada ah ayaa ah kan ugu dhaqaalaha badan.Dhuumaha aan cillad lahayn waxaa lagu soo saaraa hal iyo laba dherer oo random ah.Dhererka kali ah ee randomku wuu kala duwan yahay 16'-0″ ilaa 20′-0″.Tuubooyinka 2 "iyo kuwa ka hooseeya waxaa laga helaa dherer labanlaab ah oo random ah oo cabbiraya 35′-0″ ilaa 40′-0″.

Tilmaamid

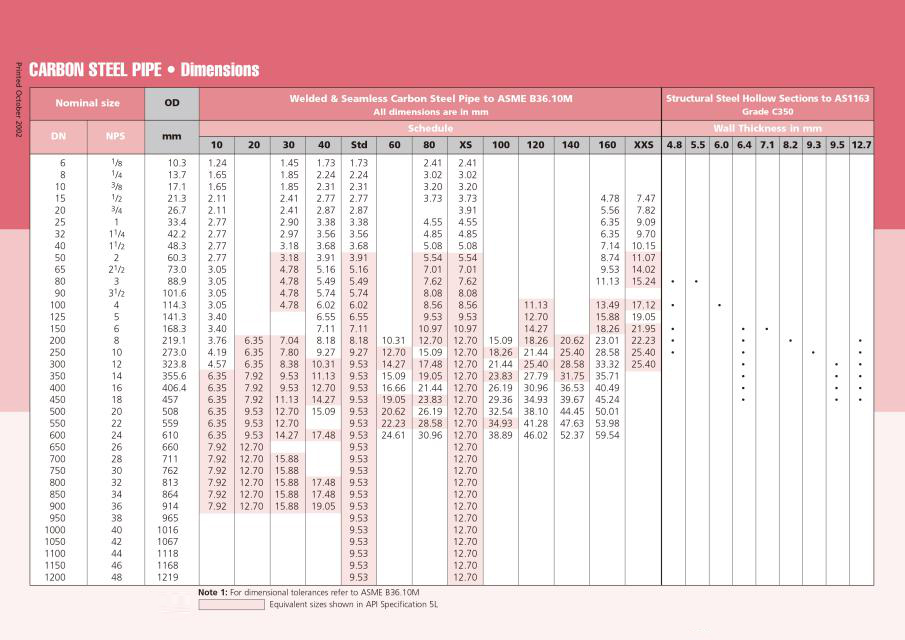

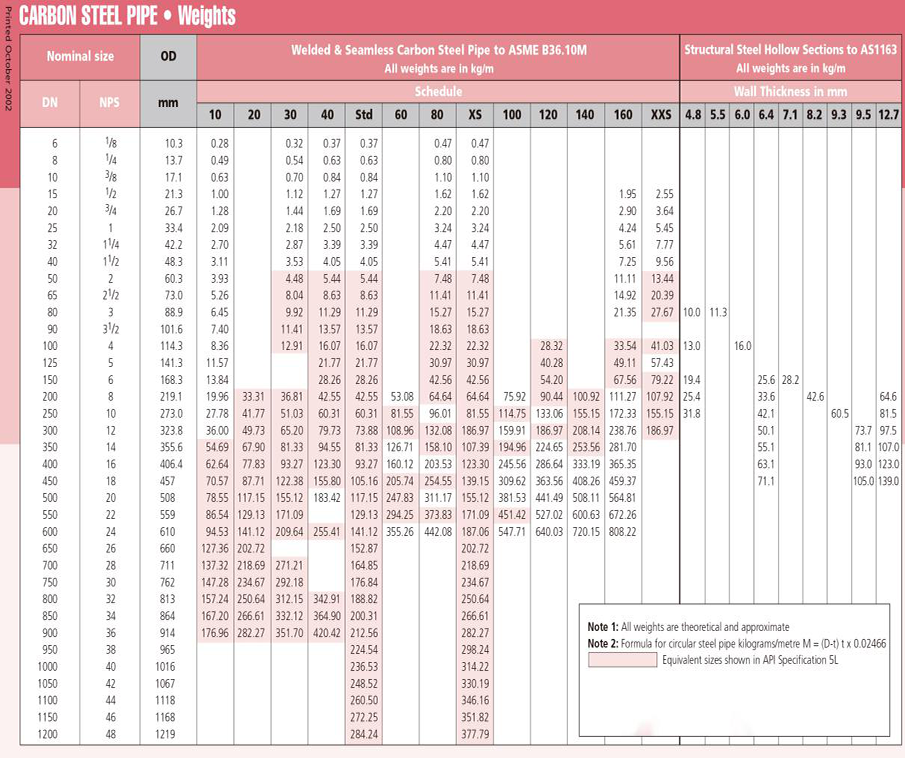

Birta kaarboon welded& cabbirka tuubooyinka iyo miisaanka

| Dhuumaha Kaarboon, Qalabyada iyo Qalabyada | |

| Foomka | Welded (ERW) iyo bilaa bilaa xad ah |

| Codsiga | Dheecaan, Dhisme |

| Baaxadda cabbirka | DN15 - DN600 |

| Darajooyinka | 250,350 |

| Dhumucda darbiga | Std Wt, XS |

| Nooca Qalabaynta | Weld dabada, marooqsan & socket, Flanges, Madaw iyo qalabka galvanized ilaa EN10241 (BS 1740) |

| Qaabka Qalabaynta | Suxulada, Tees, Reducers, Koofiyadaha, Stub dhamaadka, Flanges (ANSI, Miiska E, D iyo H) |

| Habaynta | Goy-ilaa-dherer, |

Heerka

Xaashida qeexitaanka ee tuubada alxanka tooska ah

| qeexid (mm) | OD (dhexroorka dibadda) | dhumucda gidaarka | miisaanka |

| 1/2 inch | 21.25 | 2.75 | 1.26 |

| 3/4 inch | 26.75 | 2.75 | 1.63 |

| 1 inji | 33.3 | 3.25 | 2.42 |

| 11/4 inch | 42.25 | 3.25 | 3.13 |

| 11/2 inch | 48 | 3.5 | 3.84 |

| 2 inji | 60 | 3.5 | 4.88 |

| 21/2 inch | 75.5 | 3.75 | 6.64 |

| 3 inji | 88.5 | 4.0 | 8.34 |

| 4 inji | 114 | 4.0 | 10.85 |

| 5 inji | 140 | 4.5 | 15.04 |

| 6 inji | 165 | 4.5 | 17.81 |

| 8 inji | 219 | 6 | 31.52 |

Shaxda qeexitaanka ee tuubada alxanka isku laabma

| qeexid | dhumucda gidaarka | Miisaanka mitirkiiba | Qiimaha cadaadiska biyaha heerka qaran | Qiimaha cadaadiska biyaha magac ahaan | qeexid | dhumucda gidaarka | Miisaanka mitirkiiba | Qiimaha cadaadiska biyaha heerka qaran | Qiimaha cadaadiska biyaha magac ahaan |

| 219 | 6 | 32.02 | 9.7 | 7.7 | 720 | 6 | 106.15 | 3 | 2.3 |

| 7 | 37.1 | 11.3 | 9 | 7 | 123.59 | 3.5 | 2.7 | ||

| 8 | 42.13 | 12.9 | 10.3 | 8 | 140.97 | 4 | 3.1 | ||

| 273 | 6 | 40.01 | 7.7 | 6.2 | 9 | 158.31 | 4.5 | 3.5 | |

| 7 | 46.42 | 9 | 7.2 | 10 | 175.6 | 5 | 3.9 | ||

| 8 | 52.78 | 10.3 | 8.3 | 12 | 210.02 | 6 | 4.7 | ||

| 325 | 6 | 47.7 | 6.5 | 5.2 | 820 | 7 | 140.85 | 3.1 | 2.4 |

| 7 | 55.4 | 7.6 | 6.1 | 8 | 160.7 | 3.5 | 2.7 | ||

| 8 | 63.04 | 8.7 | 6.9 | 9 | 180.5 | 4 | 3.1 | ||

| 377 | 6 | 55.4 | 5.7 | 4.5 | 10 | 200.26 | 4.4 | 3.4 | |

| 7 | 64.37 | 6.7 | 5.2 | 11 | 219.96 | 4.8 | 3.8 | ||

| 8 | 73.3 | 7.6 | 6 | 12 | 239.62 | 5.3 | 4.1 | ||

| 9 | 82.18 | 8.6 | 6.8 | 920 | 8 | 180.43 | 3.1 | 2.5 | |

| 10 | 91.01 | - | 7.5 | 9 | 202.7 | 3.5 | 2.8 | ||

| 426 | 6 | 62.25 | 5.1 | 4 | 10 | 224.92 | 3.9 | 3.1 | |

| 7 | 72.83 | 5.9 | 4.6 | 11 | 247.22 | 4.3 | 3.4 | ||

| 8 | 82.97 | 6.8 | 5.3 | 12 | 269.21 | 4.7 | 3.7 | ||

| 9 | 93.05 | 7.6 | 6 | 1020 | 8 | 200.16 | 2.8 | 2.2 | |

| 10 | 103.09 | 8.5 | 6.7 | 9 | 224.89 | 3.2 | 2.5 | ||

| 478 | 6 | 70.34 | 4.5 | 3.5 | 10 | 249.58 | 3.5 | 2.8 | |

| 7 | 81.81 | 5.3 | 4.1 | 11 | 274.22 | 3.9 | 3 | ||

| 8 | 93.23 | 6 | 4.7 | 12 | 298.81 | 4.2 | 3.3 | ||

| 9 | 104.6 | 6.8 | 5.3 | 1220 | 8 | 239.62 | - | 1.8 | |

| 10 | 115.92 | 7.5 | 5.9 | 10 | 298.9 | 3 | 2.3 | ||

| 529 | 6 | 77.89 | 4.1 | 3.2 | 11 | 328.47 | 3.2 | 2.5 | |

| 7 | 90.61 | 4.8 | 3.7 | 12 | 357.99 | 3.5 | 2.8 | ||

| 8 | 103.29 | 5.4 | 4.3 | 13 | 387.46 | 3.8 | 3 | ||

| 9 | 115.92 | 6.1 | 4.8 | 1420 | 10 | 348.23 | 2.8 | 2 | |

| 10 | 128.49 | 6.8 | 5.3 | 14 | 417.18 | 3.2 | 2.4 | ||

| 630 | 6 | 92.83 | 3.4 | 2.6 | 1620 | 12 | 476.37 | 2.9 | 2.1 |

| 7 | 108.05 | 4 | 3.1 | 14 | 554.99 | 3.2 | 2.4 | ||

| 8 | 123.22 | 4.6 | 3.6 | 1820kii | 14 | 627.04 | 3.3 | 2.2 | |

| 9 | 138.33 | 5.1 | 4 | 2020 | 14 | 693.09 | - | 2 | |

| 10 | 153.4 | 5.7 | 4.5 | 2220 | 14 | 762.15 | - | 1.8 |

Rinjiyeynta & Dahaarka

Saliid khafiif ah, Galvanized Dip Hot, Electrogalvanized, Black, Bare, Daahan Varnish / Saliid miridhku ka hortagtaa,Dahaarka ilaalinta

Baakaynta & Soo dejinta